Beyond Static

Precision 3D Force Sensing

Go beyond simple pressure. Understand the full force vector – magnitude, direction, and location – across all three dimensions with unprecedented accuracy.

Seeing Only Part of the Picture?

The Limits of Conventional Force Data

Traditional sensors often excel at measuring vertical load (Z-axis) but struggle to accurately capture the complex shear forces acting in the horizontal plane (X and Y axes).

This means:

- Crucial dynamics like friction, shear stress, and multi-directional impacts remain hidden.

- Products and systems are developed based on assumptions rather than true multi-axis force data.

- Assessing stability, optimizing dynamic movements, or preventing failures becomes guesswork without the full force vector.

- Often requiring multiple, specialized devices for different aspects of force analysis, increasing complexity and cost.

True 3D Force Intelligence

We’ve engineered a revolutionary apparatus from the ground up, specifically designed to measure and analyze true three-dimensional (3D) load characteristics.

Our patented technology captures:

- Accurately measure magnitude and direction across X, Y, and Z axes simultaneously.

- Determine Center of Pressure (COP), torque, load distribution, shape, and vibration with high fidelity.

- Provide a comprehensive understanding of complex interactions using a single, robust platform.

- Deliver the data needed to innovate, optimize, and ensure safety like never before.

Our Sensor Technology

Our breakthrough isn’t just a sensor; it’s an integrated system built on novel design principles. We combine sophisticated mechanical architecture with multi-axis sensing and intelligent processing to overcome the hurdles faced by conventional technology.

1. Multi-Axis Sensor Architecture

At the heart of the Humatric system lies a strategic configuration of specialized load cells. We utilize distinct sets of sensors, precisely positioned and oriented, to isolate and measure forces along each spatial vector independently. Vertical load cells capture Z-axis forces (compression/tension), while dedicated horizontal load cells accurately measure the often-neglected X and Y-axis shear forces. This specialized arrangement is fundamental to achieving true 3D measurement.

2. Mechanically Decoupled Design

Accurate multi-axis measurement demands mechanical ingenuity. Our unique apparatus structure (often featuring upper and lower plates) incorporates precisely engineered interfaces. Elements like spherical ball bearings allow minute, controlled displacement for Z-axis measurement while enabling low-friction movement in the X-Y plane. Specialized pin-and-hole connections engage horizontal sensors during shear movements, ensuring forces are directed to the correct sensor without significant interference (crosstalk). This intelligent decoupling is key to signal purity and accuracy.

3. Integrated Sensor Fusion & Processing

For even richer insights, the Humatric platform can incorporate additional sensor arrays on the measurement surface or surrounding structures. Options include strain gauges, piezoelectric, capacitive, or tactile sensors. This data, alongside the primary load cell inputs, is fed into an integrated control module. Advanced algorithms synchronize, calibrate, and process this data, calculating resultant forces, COP, torque, and dynamic characteristics. Information is readily available via standard wired or wireless communication protocols.

4. Compact Integration Potential

Leveraging advanced sensor technologies, such as thin film-based load cells, allows Humatric sensing capabilities to be integrated into incredibly compact and low-profile form factors. This opens up possibilities for embedding true 3D force sensing directly into products where space is at a premium.

Key Use Cases

Automotive

Safer Vehicles, Smarter Dynamics

Enhanced Safety

Enable adaptive safety systems by accurately measuring passenger weight, position, and dynamic shifts. Optimize airbag deployment force, seatbelt pre-tensioner activation, and occupant detection.

Improved Dynamics & Comfort

Inform dynamic weight distribution analysis for better stability and handling. Provide real-time load data for adaptive suspension systems.

R&D and Testing

Gain deeper insights during vehicle testing and crash analysis.

Biomechanics

Deeper Insights into Human Movement

Clinical Gait Analysis

Go beyond 2D pressure maps. Precisely diagnose pathologies, assess treatments, and design personalized interventions by analyzing X, Y, and Z forces during walking and running. Quantify force losses due to non-propulsive movements.

Orthopedic Assessment

Objectively measure forces on joints and tissues for diagnosis, surgical planning, and implant design.

Rehabilitation Monitoring

Quantify patient progress and tailor interventions based on objective 3D force data. Develop advanced balance assessment and training tools.

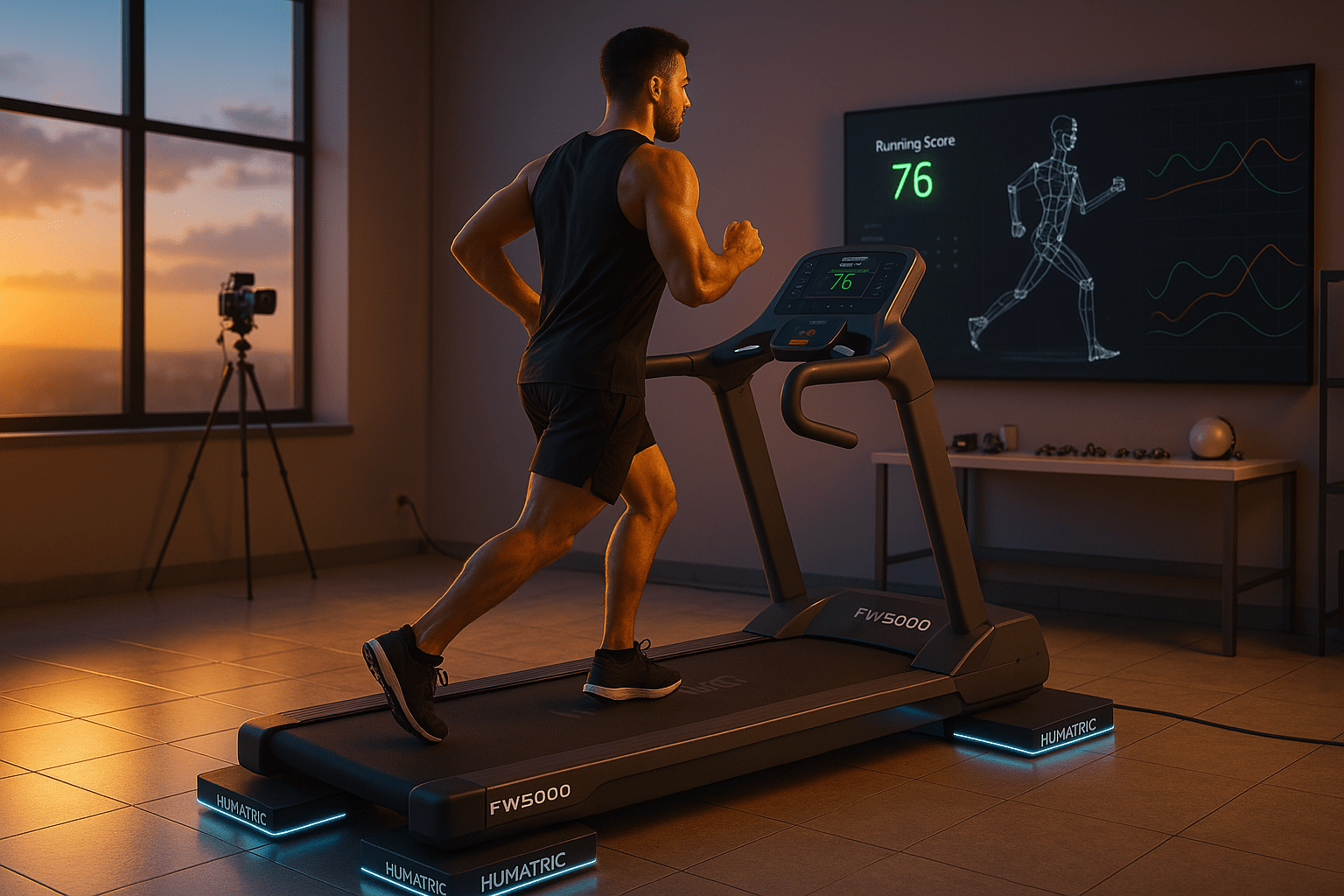

Sports Science

Optimizing Performance, Preventing Injury

Technique Optimization

Analyze the precise 3D forces in movements like running, jumping, throwing, or cycling to refine technique and maximize efficiency.

Equipment Design

Develop better footwear, protective gear, and equipment based on real-world force data.

Load Management

Monitor athlete training loads objectively to optimize conditioning and reduce injury risk. Analyze forces on training equipment like treadmills.

Industrial Automation

Precision Control, Enhanced Dexterity

Advanced Robotics

Enable robotic grippers to handle delicate or complex objects with precise 3D force feedback. Improve assembly verification through force monitoring.

Human-Robot Collaboration

Create safer, more intuitive interactions in shared workspaces by allowing robots to sense and react to applied forces in all directions.

Quality Control & Process Monitoring

Embed sensors to monitor forces during manufacturing processes (pressing, machining), ensuring consistency and detecting anomalies.

Ergonomics

Designing Safer, More Intuitive Interactions

Workplace Safety

Analyze manual material handling tasks, tool usage forces, and repetitive strain risks to design safer work environments and reduce musculoskeletal disorders.

Product Design

Optimize the design of handheld tools, control interfaces, joysticks, and furniture for comfort and usability based on 3D force data.

Beyond Today

The applications of true 3D force sensing are vast and growing:

- Consumer Electronics: Force-sensitive displays, buttons, and wearables.

- Aerospace & Defense: Structural testing, payload balancing.

- Civil Engineering: Structural health monitoring.

- Materials Science: Complex load characterization.

And many more…

Collaborate with Humatric

Nur Engineering GmbH is committed to bringing this transformative technology to the world. We offer flexible engagement models to integrate Humatric 3D force sensing into your vision:

Technology Licensing

Integrate our patented technology directly into your products. Gain a significant competitive advantage with comprehensive support from our team.

Consulting & Integration

We’ll work with you to seamlessly integrate Humatric sensing into existing systems or develop application strategies, accelerating your time-to-market.

Custom Engineering Solutions

We provide bespoke design and development services for novel sensors, platforms, or complete solutions tailored precisely to your needs.

Strategic Partnerships

We actively seek ambitious partners for Joint Ventures and strategic collaborations. Let’s discuss how we can disrupt markets together.

Your Partner in Force Sensing Innovation

Choosing Humatric means partnering with Nur Engineering GmbH, a team dedicated to pushing the boundaries of sensor technology.

- Pioneering Technology: Access unique, patented, and validated 3D force measurement capabilities.

- Expert Team: Benefit from the deep knowledge and practical experience of our dedicated engineers and scientists.

- Collaborative Spirit: We prioritize understanding your goals and working together to achieve optimal results.

- Commercialization Focus: We are driven to translate cutting-edge technology into real-world applications and market success.

- German Engineering: Rely on quality, precision, and reliability rooted in sound engineering principles.

We’re democratizing 3D Force Insight – giving every innovator the power to see and shape the invisible forces that define human performance and safety.”

Marius Schober

Co-Founder, Humatric

Ready for True 3D Force Data?

Stop making assumptions based on incomplete information. Unlock the full potential of your products, research, and innovations with the unparalleled insights provided by Humatric’s 3D force sensing technology.

Contact us today to discuss your application, explore partnership opportunities, or request a consultation.

About Nur Engineering GmbH

Nur Engineering GmbH is a German technology innovation company specializing in advanced sensor solutions. Humatric is our flagship brand, embodying our breakthrough capabilities in human-centric multidimensional force measurement. We combine rigorous engineering with a passion for innovation to empower progress across science and industry.